Linear Motion Mechanisms in the Industry

It is difficult in the modern industry to imagine working without linear motion mechanism. There is some the most commonly used custom actuators which include; control valves, presses, and overhead systems.

In the production industry, linear motion mechanisms are used almost in every process from the entrance door to the linear displacement in the laser head cutting head machines. It is also used in driving modern machine centers. Additionally, linear motion mechanisms are also used in building machines. The advantage of using linear motion mechanisms such as electromechanical actuators or the hydraulics is the simplicity, the ability to control huge tasks and the possibility of stopping at any point. Driver linear motion mechanisms have various names such as gears, electric gear and electric cylinders

Screw jacks

Screw jacks are equipment that is usually used where greater effort is required. It is important to note that jacks are usually designed to raise or lower a load. These mechanisms work well and in a horizontal direction or at any other angle horizon. The greatest “authority” if the screw jack is that it can create a compression and a tensile force. The tensile force is usually advantageous since you need not caring about the stability of the screw jack.

There are various types of these devices, but their names do not change. The main features of these devices include a moving rod which has a fixation mechanism; it has housing and the hinge shaft.

It is driven with the motors perpendicular to the axis of the drive which is a logical extension of the screw jack.

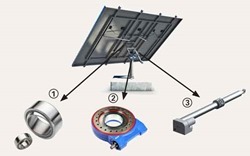

Actuators for moving solar

The mechanism for linear movement has been development in the industry due to rise in energy price to reduce the burden and increasing alternative source of energy. Some of the examples include geothermal and solar energy turbines.